Here

you

see the my special table with bulkhead

B. The packages are bricks

wrapped in plastic bags. These bricks

are needed to fix the different

pieces of wood for the first time.

Than the squared timbers are applied

to ensure to get sufficient pressure -

but be aware that the pressue

must not be to high - otherwise the

epoxi runs away...

Bulkhead

A and B are almost ready!

Bulkhead

A and B are almost ready!

Bulkhead A is rather simple to

build -

instead of

bulkhead B and so on. Bulkhead C and

the following ones are better to

be build in two sections. First the

lower part, than the upper one.

The

lower

part of bulkhead C on the table. A

piar of compass is used to

draw the arc:

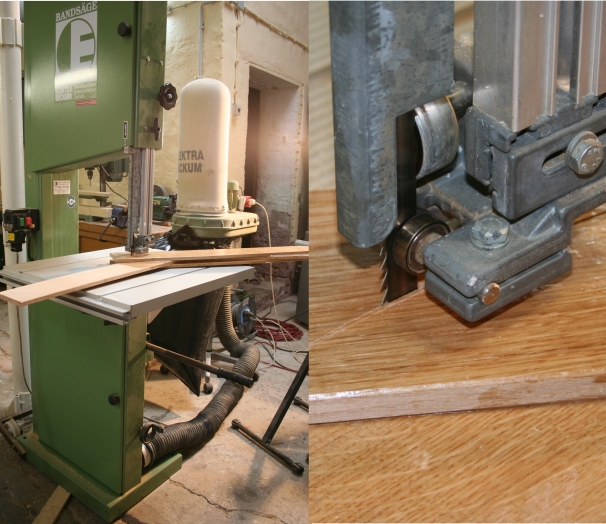

The band

saw is very appropriate to cut the

arcs:

Bulkhead

C

is

made out of three layers of oak.

Bulkhead

C

is

made out of three layers of oak.